COMPLEX DESIGN

Inexpensive technology for large numbers of products with complex shapes

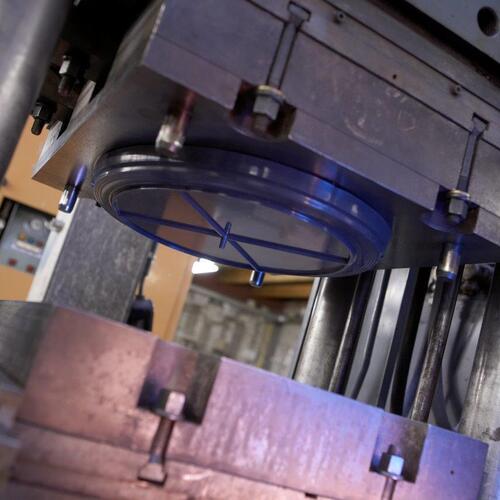

If you need a rubber product with a more complex design, then injection moulding is the production method for you. This is an attractive option if you want to manufacture large numbers of more complex products.

In injection moulding, the rubber compound is injected into the mould under high pressure (up to 2000 bar). If complex forms are involved, the design of this mould will require a high investment. The cost of the mould will, however, be compensated for by the fact that the process can be largely automated. This is a fast, inexpensive method of production, particularly in the case of large numbers.

Are you looking for a cutting edge solution in rubber?

Call our rubber specialists on +31 (0)72 571 10 26 or email info@vankempen-rubber.nl

English

English